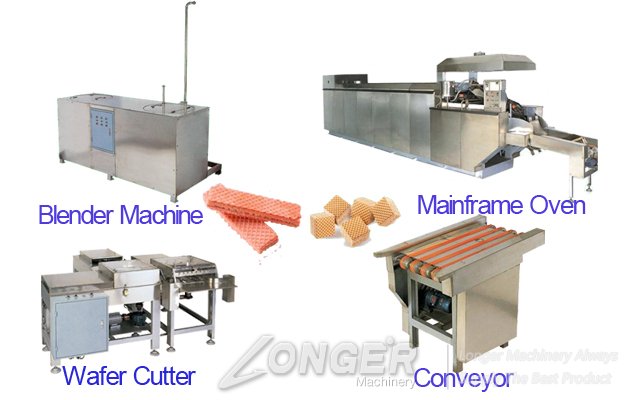

Features

Adopting hearing-medium conduction technology with heating oil as medium,the plant is a new generation product developed exclusively in China based on the advanced structure of existing plants from domestic market and abroad.If offers an ideal solution for lower power consumption and overall production cost,and keeping the same surface color for all biscuits.The plant mainly consists of mixing system,automatic feeding system, tunnel-type oven, sheet feeding and cooling device,coating machine,cutter and organic heating medium boiler, etc.With compact structure and unique reliability, the plant is one of the most preferred equipment in foodstuff industry.

Advantages

1.The blender machine is the mixing system, the first technology processing equipment in wafer manufacturing. It adopts the separate delivery and automatic circulation system.

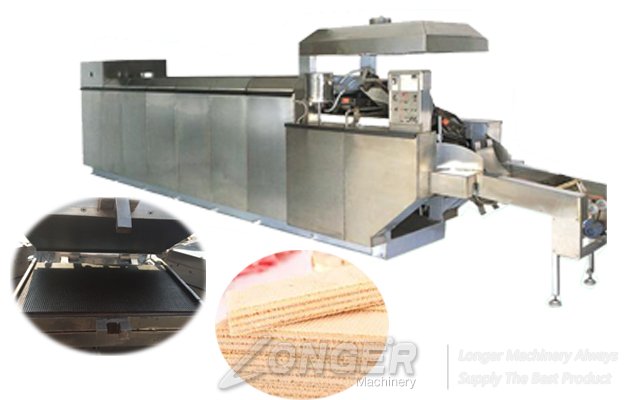

2.As to the most important part:Baking oven.Unanimous heat colors of wafer block. Thanks to the scientific selection of heating components, superior material selection for baking plate and reasonable die carrier structure, the heat colors of the center and periphery of the wafer block having been baked are unanimous.

3.High rate of certified products with finished product rate of not less than 98%. Because of uniform heating and unanimous heat colors, the demoulding rate of biscuit is high with improving rate of certified products accordingly.

Technical Data

| No. | name | quantity |

| 1 | 15 moulds flat automatic electric heating oven | 1 |

| 2 | Splicing machine | 1 |

| 3 | Wafer sheet cooling machine | 1 |

| 4 | Cream spreading machine | 1 |

| 5 | Wafer cutting machine | 1 |

| 6 | Blender Machine | 1 |

| 7 | Cream mixer | 1 |

| 8 | Swashing Machine | 1 |

| 9 | Sugar grinder | 1 |

| 10 | Air compressor | 1 |

Parameter:

| Model | LGDL-15-1 |

| Moulds quantity | 15 |

| Moulds size | 470*325*25mm |

| Size of wafer stripe | 3.0*3.0*0.5 |

| Wafer thickness | 2.0-3.0mm |

| Baking time | 95~120 seconds(the thickness of wafer<2.5mm) |

| Capacity | 560 pieces/h(the thickness of wafer:2.3mm) |

| Component materials in contact with food | 304 # stainless steel or cast iron |

| Average Power | 1.5kw |

| Voltage | 3-phase,380V,50 Hz |

| Gas consumption | About 40m3/h |

| Dimension | 3260*1560*2320mm |

| Weight | 5700kg |

You are here:

You are here: